Bel ons

+86-19858305627

Email ons

sales@maple-machinery.com

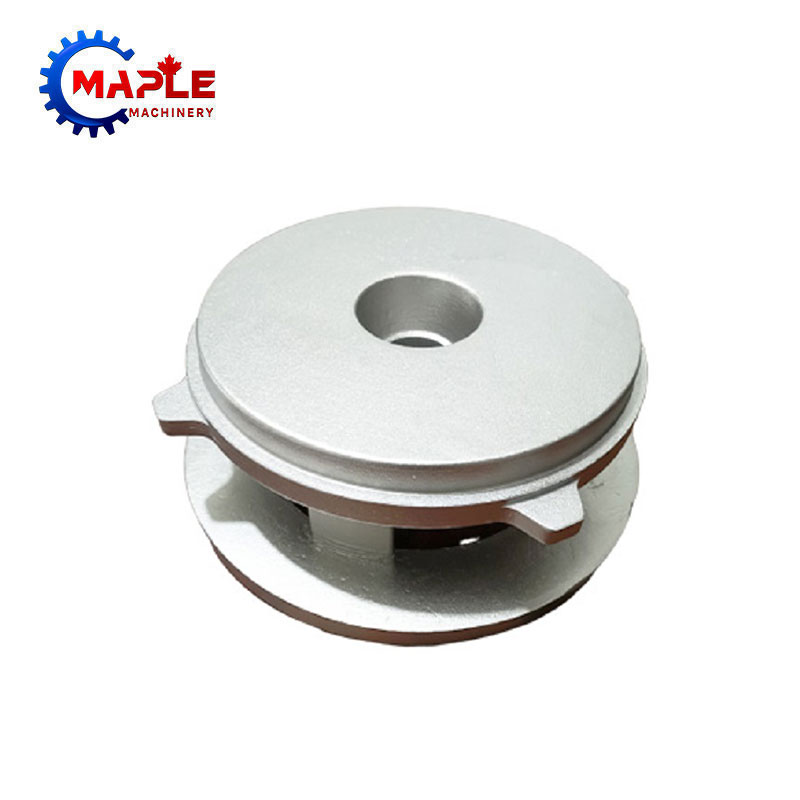

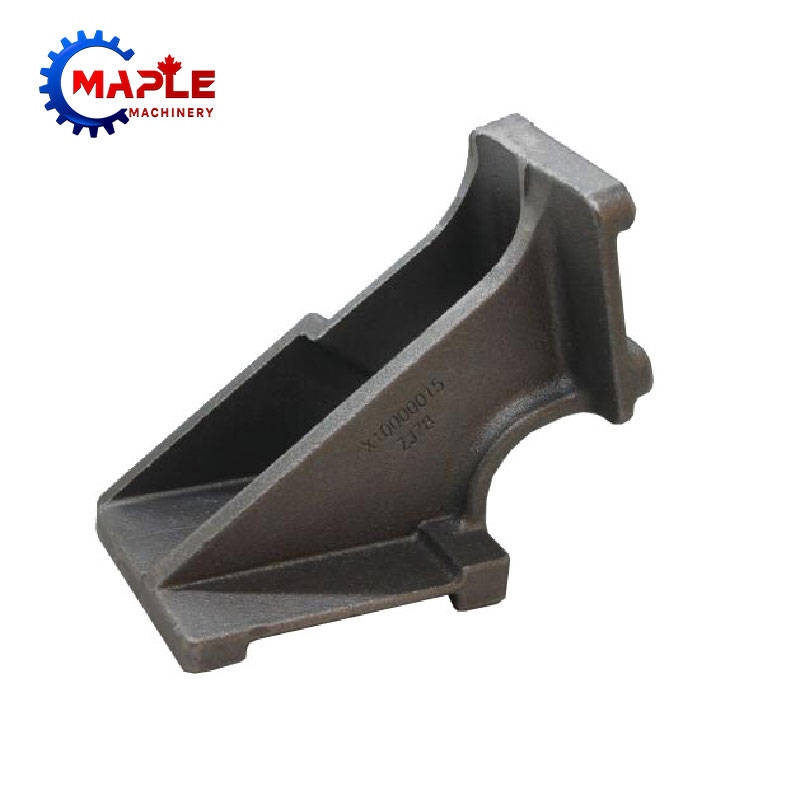

Milieuvriendelijke recycling van gietijzer Fabrikanten

Onze fabriek biedt zandgieten, smeden met gesloten matrijzen, smeden met open matrijzen, enz. Extreem design, hoogwaardige grondstoffen, hoge prestaties en een concurrerende prijs is wat elke klant wil, en dat is ook wat wij u kunnen bieden. We nemen hoge kwaliteit, redelijke prijs en perfecte service.

hete producten

Voedselverwerkingsmachine Stalen precisie-gietonderdelen

Wij zijn de toonaangevende fabrikant en leverancier op het gebied van Food Process Machine Steel Precision Casting Parts. Ons productassortiment wordt op kwaliteit gecontroleerd aan de hand van verschillende industriestandaarden. We hebben meer dan 15 jaar ervaring in het op maat maken van onderdelen voor de voedselverwerkende industrie. We hebben een breed assortiment aandrijfassen, aandrijflijnen, transmissies en componenten op voorraad. We hebben een aantal talentvolle professionals aangesteld. Onze experts proberen de wensen van de klant te begrijpen.Onderdelen van nodulair gietijzer voor de zware industrie

Gelegen in Ningbo, China, dicht bij de haven, heeft het een eigen productiefabriek en een technisch team dat zich toelegt op het bieden van oplossingen aan klanten om te werken met kwaliteit en de nieuwste technologie. Het bedient de hele wereld. Dankzij onze expertise, ons moderne machinepark en hoogwaardige productietechnologie levert de productiefase de juiste hoeveelheid hoogwaardige gietijzeren onderdelen voor de zware industrie.Onderdelen voor het gieten van staal voor landbouwmachines

Maple Machinery deed meer jaren geleden zijn intrede in de landbouwindustrie en heeft tegenwoordig een brede en succesvolle markt in Europa en Noord-Amerika. We hebben een groeiende lijst van trouwe klanten die vertrouwen op hoogwaardige stalen gietstukken voor landbouwmachines voor hun landbouwindustrie. We kunnen het vertrouwen van klanten alleen winnen dankzij onze professionele diensten en hoogwaardige producten op basis van geavanceerde technologieën.Bouwmachines Stalen zandgietonderdelen

Onze expertise op verschillende gebieden wordt veel gebruikt. We hebben de productietechnologie op het gebied van bouwmachines gediversifieerd en bieden hoogwaardige bouwmachines, stalen zandgietonderdelen en diensten voor klanten van bouwmachines. Om klanten kwaliteitsproducten en -diensten te bieden, om klanten kwaliteitsproducten en -diensten te bieden.Ventiel gietijzeren gietdelen

Maple Machinery, met zijn uitgebreide technische kennis en hooggekwalificeerd team, ontwikkelt op maat gemaakte oplossingen voor het gieten van nodulair gietijzer voor ventielen in overeenstemming met de behoeften van onze klanten. Prioriteit geven aan vertrouwelijkheid, verantwoordelijkheid en duurzaamheid in relaties met alle geïnteresseerde partijen, met de doelstellingen van Valve op middellange en lange termijn in het achterhoofd. Technische vereisten die in onderling overleg met de klant zijn gedefinieerd, bieden diensten op maat. Het serviceteam streeft naar snelle respons en directe transparantie van projectontwikkeling tot aftersales. Lever gietoplossingen volgens de eisen en specificaties van de klant.Ventiel RVS gietdelen

Maple Machinery heeft gewerkt aan de productie van Valve Stainless Steel Casting Parts. Als leider op het gebied van rail-, windindustrie-, offshore-, bouw- en industriële machines, is het machineteam van Maple ervaren en dynamisch. Onze houding ten opzichte van onze klanten en ons doorzettingsvermogen zorgen voor een uitstekende service en kwaliteit

Stuur onderzoek

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy